Mobile Slaughter Units

More than two dozen MSUs currently operate around the country. About half are designed to process red meat, with the rest processing poultry and smaller animals such as rabbits. Many are managed by producer cooperatives formed specifically to operate slaughter services by and for area ranchers. MSUs have become increasingly popular over the last decade because they are typically cheaper to build and operate than fixed facilities, more adaptable to the varying needs of diverse livestock operations and, by traveling from farm to farm or region to region, allow for on- or near-farm slaughter which many consider to be more humane than transporting animals far away.

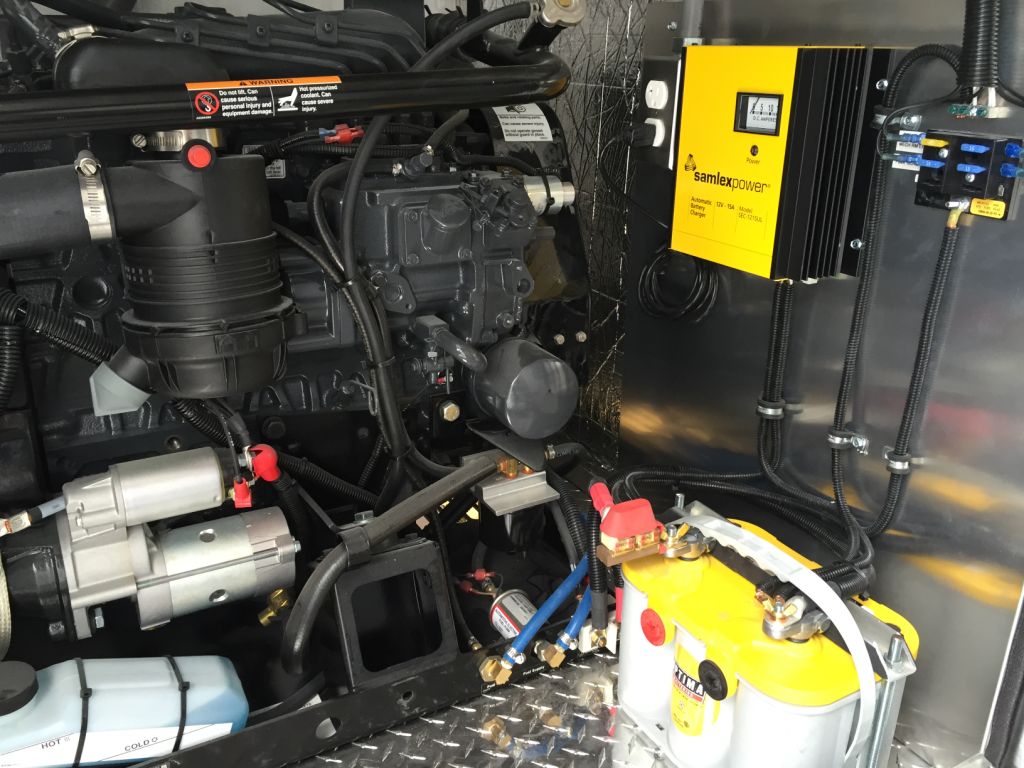

HIMC’s 36-foot trailer is being manufactured by TriVan, the most experienced MSU manufacturer in the country. The unit is divided into three sections from front to rear: mechanical/storage, hanging carcass cooler, and processing. The design of the unit takes into account the need for robust construction while minimizing weight. It also complies with USDA requirements for fit and finish of materials to facilitate sanitary operations and cleanup. The unit will be capable of processing four species of animals: cattle, pigs, sheep, and goats. Expected daily throughput is 8-10 head of cattle, 15 pigs, and 30 lamb or goats.

Slideshow: HIMC’s MSU being constructed, courtesy of TriVan

Composting

When using the MSU, producers are responsible for proper disposal of inedible offal and other slaughter residuals. This must be handled in a manner than ensures it does not enter the food chain or pose a threat to the environment. Composting is encouraged as a low-cost way to safely return nutrients back to the land. See the following resources for more information.

- HIMC Composting Guidelines

- The Space It Takes – Footprint Calculator for Composting Butcher Waste by Cornell Waste Management Institute, 2010.

- Natural Rendering: Composting Livestock Mortality and Butcher Waste by Cornell Waste Management Institute, 2002; 2008.

- Key Points of Static Pile Carcass Composting in Reference to Natural Rendering: Composting Livestock Mortality by Cornell Waste Management Institute, 2002.

- Key Points of Static Pile Butcher Waste Composting in Reference to Natural Rendering: Composting Butcher Waste by Cornell Waste Management Institute, 2002.

- Composting Animal Mortalities by Minnesota Board of Animal Health, Minnesota Dept. of Agriculture, and University of Minnesota Extension Service, 2009.

- Environmental Engineering National Engineering Handbook, Ch. 2 Composting by USDA & NRCS, 2010.

- Composting dead livestock: A new solution to an old problem by Iowa State University Extension Office, 1999.

- Composting Large Animal Carcasses by Texas A&M University System’s Texas Cooperative Extension, 2006.

Several calculators are available to help determine how much space is needed for composting slaughter residuals:

- Co-Composter Model by Cornell University’s Department of Biological and environmental engineering and Cornell Waste Management Institute, 2001. Note: when calculating for slaughter residuals start with question #8 on the user input page.

- Spartan Animal Tissue Composting (ATC) System Planner by Roseboom, Person and Kreigel at Michigan State University, 2009.

Additional Resources:

- Niche Meat Processor Assistance Network – http://www.nichemeatprocessing.org/

- Socially Responsible Agriculture Project – http://www.sraproject.org/

- Hawai‘i Island Mobile Slaughter Unit Feasibility Study

MSUs Currently in Operation (red meat only):

- Island Grown Farmers Cooperative, WA – http://www.igfcmeats.com/

- Puget Sound Meat Producers Cooperative, WA – http://www.pugetsoundmeat.com/

- Mobile Matanza, NM – http://www.tcedc.org/mantanzaProgram.html

- Wild Idea Buffalo, SD – http://wildideabuffalo.com/

- Alaska Meat Company, AK – http://www.alaskameat.com/Services_Available.php

- Central Coast Grown, CA – http://centralcoastgrown.org/

- Callicate Beef, NB / CO – http://callicratebeef.com/